As we enter into "Silly Season" for outages, the importance of managing components that leave site for overhaul and repair is critical.

Here are some before and after photos of a Barring Drive and Governor Linkage Arm recently returned to the TMS workshop as part of a minor outage scope.

Planning and communication really does come to the fore this time of year as the critical path for returning a machine to service can be influenced by so many different situations.

These two components will be on site and ready for installation days ahead of schedule allowing us to meet our Customers requirements easily and smoothly.

Post Test Bearing Inspection.

Here at TMS, wherever physically possible, and based upon machine design, we offer an overspeed air test following rebuild on GP Steam Turbines. Here we are inspecting the bearing following test completion.

Not all machines go back into active service immediately, therefore the Customer is reassured that all is in safe working order and fit for purpose upon reinstallation.

We look after your rotating machinery!

Varied Market Support!

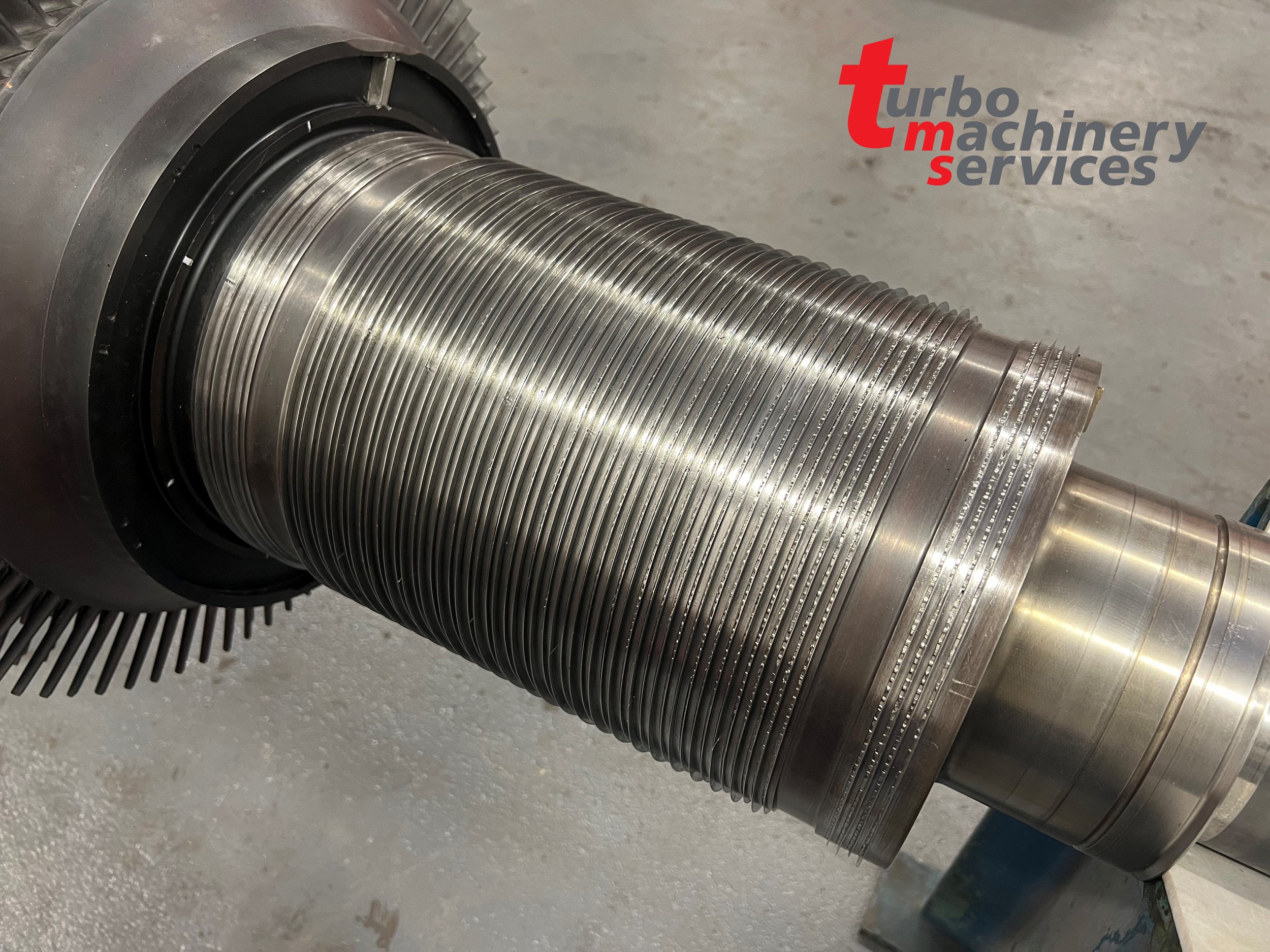

A Gear Pinion inspection being conducted for one of our waste to energy customers along with a single stage turbine casing in the background, part of a strip, inspect & refurbishment project for a Valued Oil and Gas Customer.

Whatever the market, we are here to support!

#biomass #wastetoenergy #gears# #oilandgas

10Mwe High Speed Pinion, fully inspected.

SafeContractor -Continued Commitment

Here at TMS we are, and will always be, committed to working safely with our Customers. Our goal is to integrate closely with our clients, understand ,Identify and mitigate potential hazards well before the execution of any work. #SafeContractor

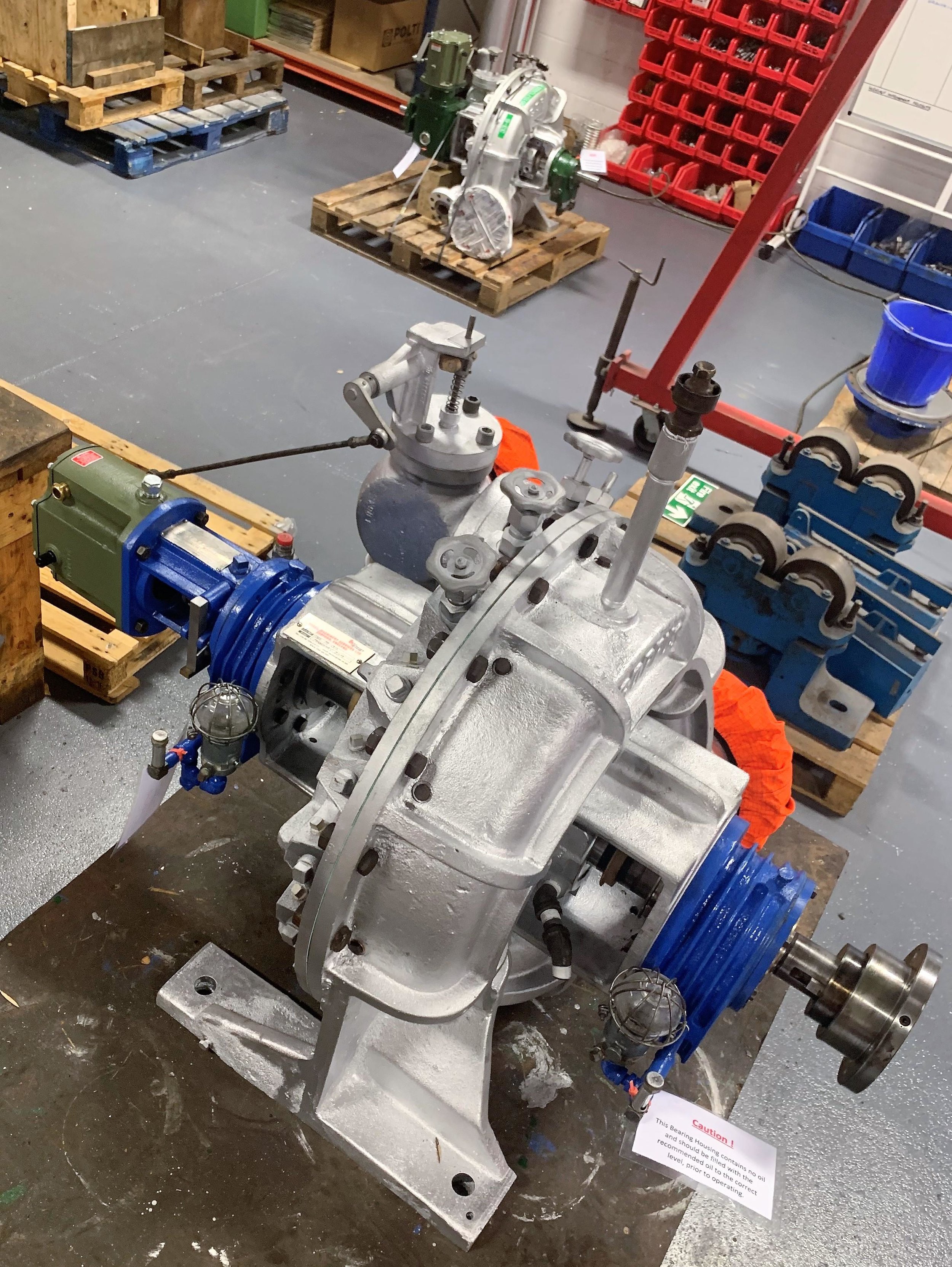

SGT200 Epicyclic Gearbox Overhaul.

An Allen SGT200 Epicyclic unit fully stripped and ready for a Customer Witness. TMS have the experience and background to support all end users with their Gearbox maintenance.

Toothed components and Spindle Bearings stripped and ready for inspection

Turbine Valve Components

A selection of Reverse Engineered Turbine Valve Components for one of our LTSA Customers. These items were manufactured and supplied within 4 weeks of the initial request at a fraction of the OEM cost and lead time.

Continued dialogue with our Customers allows us to focus on their business requirements and ensure that all of their needs are met and provided for on a timely basis. #outageplanning

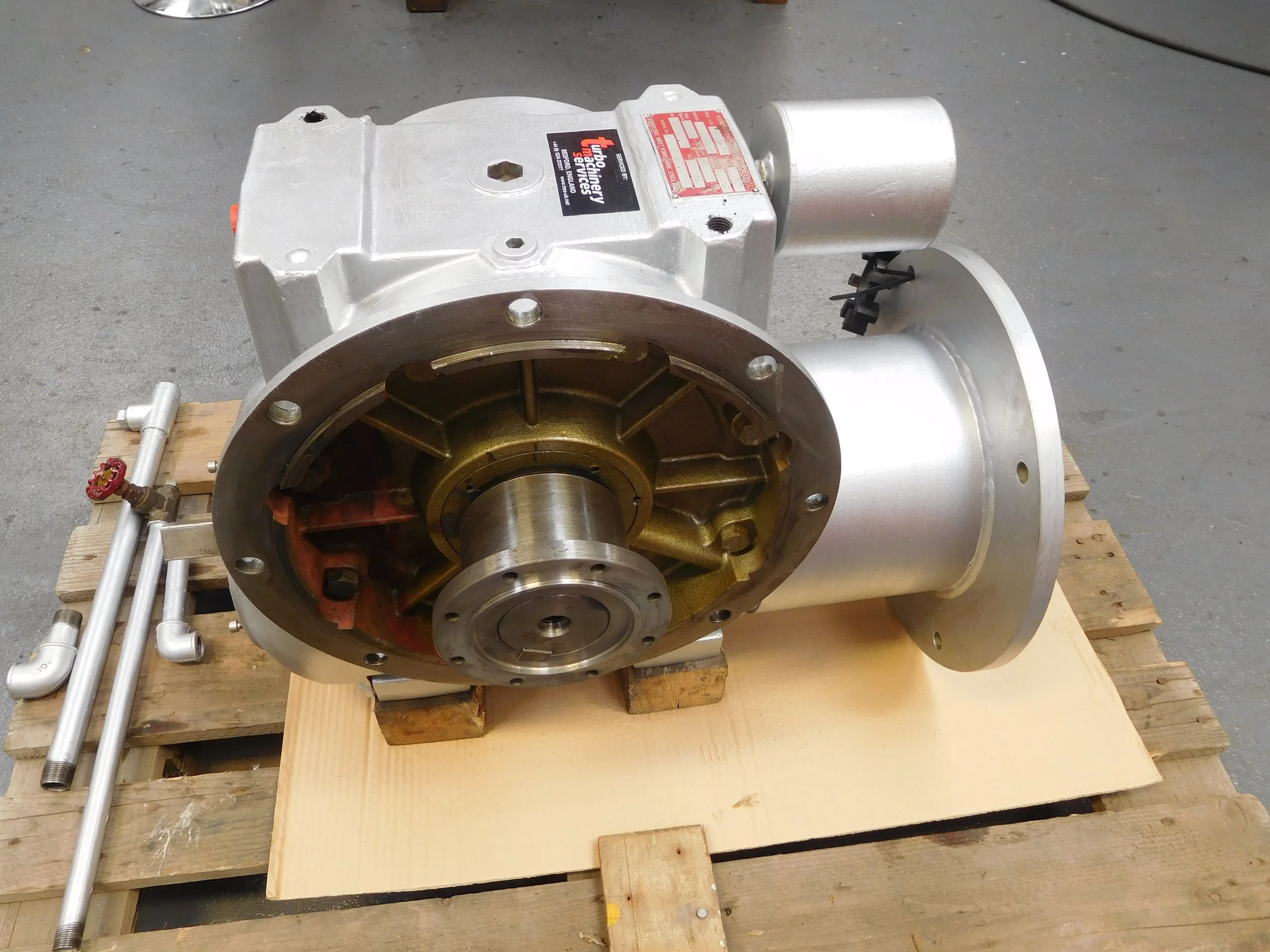

Terry SA730- Single Stage Turbine Over

Another Terry SA730 Single Stage Turbine, fully overhauled and about to be returned to the Customer.

Rebuild has been completed with Labtecta seal technology

Replacement shaft and balanced Assembly

Reconditioned Woodward Governor.

Machine tested for governing and overspeed

Pressure test of Bearing chambers pre and post build.

Full detailed Documentation pack, signed off by Customer.

Full rotor seal strip replacement

Full seal strip replacement on one of our customer's rotors completed at our Bedford workshop. The rotor also had one row of blades replaced and then the unit was successfully high speed balanced.

#reblade #hsb #highspeedbalance #sealstrip

Alstom TM2 Turbine Major Overhaul and Reblade

TMS carried out a major overhaul on our long standing customers Alstom TM2 units. Unfortunately the integral shrouding on the LP turbine was found to be cracked and so TMS reverse engineered replacement blades, utilising laser scanning technology, and fitted them with just a few weeks extension to the original outage plan. The units were successfully commissioned and went on to break the weekly generation record shortly after commissioning. hashtag#turbine hashtag#generation hashtag#blading

LTSA AGREEMENT REAPING BENEFITS

TMS have set up several Long Term Service Agreements with our customers who are operating Biomass and Waste to Energy plants. One such biomass fired CHP plant with a TGM Kanis turbine were seeking to improve upon response times and costs associated with OEM support and so when the warranty period expired they went to tender for the scheduled minor overhaul. TMS performed well during this outage, carrying out emergent works on a breakdown basis and in half of the OEM’s quoted lead time. As a direct result of our performance TMS were asked to supply a proposal for a five year LTSA which was drafted to meet the customers requirements and tailored as requested. TMS have now been supporting the customer for nearly 3 years, supplying failure analysis investigation, control system upgrades and remote monitoring and analysis, spare parts supply, 24 hour technical support and planned and unplanned service works. This has enabled the customer to pro-actively maintain the set to their requirements and not those dictated by an OEM.

WORKSHOP UPDATE

The view from our bay 3 workshop today. This bay is kitted out with shroud punching equipment, blading area, electrical run out measurement and Schenk balancing facility to enable us to carry out thorough inspections and refurbishments of rotors.

CENTRIFUGAL COMPRESSORS

Turbo Machinery Services Engineers have recently completed the DE and NDE dry gas seal change on a centrifugal gas compressor in challenging conditions for our customer. With sub zero temperatures, high winds, snow and rain to contend with our engineers stuck to the task whilst ensuring the work was done safely. The unit had been experiencing major oil loss prior to our works and TMS engineers were able to identify the issue and resolve this to the customers satisfaction whilst carrying out their work scope.

LOW SPEED BALANCING

Turbo Machinery Services Limited have recently balanced a Power Turbine rotor on our Schenk 8 tonne balancing machine to G2.5 specification as requested. TMS are able to carry out low speed balance for a wide variety of rotating machinery up to G1 specification as required, providing breakdown responses and flexible services to our customers. Please get in touch for any balancing requirements.

COPPUS TURBINE OVERHAUL AND TEST

TMS have recently completed the refurbishment and overspeed test of two Coppus turbines for differing customers. The works were carried out in our Bedford workshop.

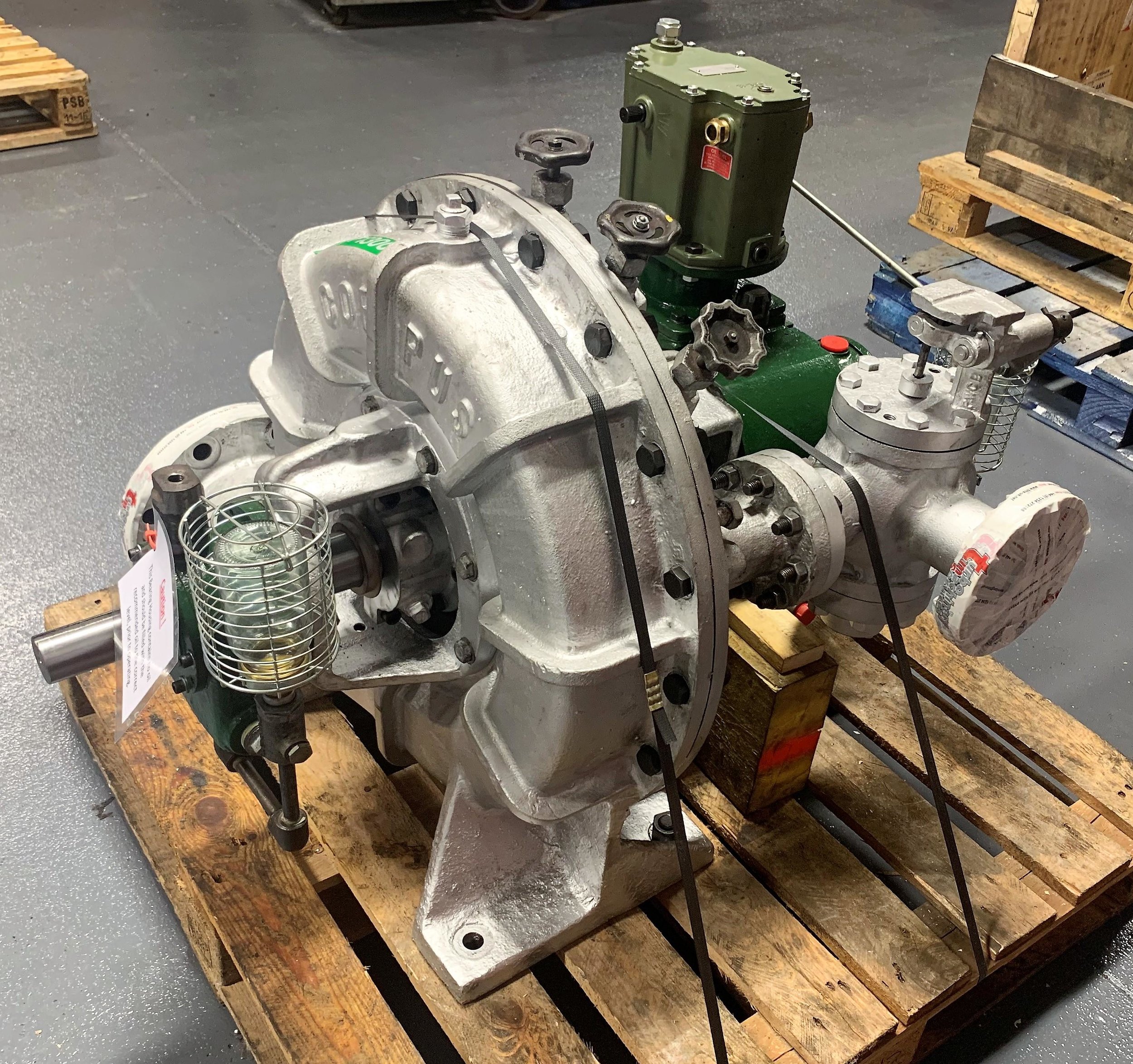

EPICYCLIC GEARBOX INSPECTION AND OVERHAUL

Turbo Machinery Services Limited have recently completed the strip, inspection and refurbishment of a Typhoon epicyclic gear box for a UK customer.